3D measurement solutions, including 3D scanners, are taking the manufacturing, NDT, quality control, and educational sectors by storm. For example, according to Research And Market, amid the COVID-19 crisis, the global market for 3D Scanners estimated at US$4.6 Billion in the year 2020, is projected to reach a revised size of US$7 Billion by 2027, growing at a CAGR of 6.3% over the analysis period 2020-2027.

Among all the 3D Measurement solutions, 3D scanner is one of the latest technologies. However, with unrivaled performance in terms of measurement speed, portability as well as adaptability, and data integrity, 3D scanners are becoming more widely-known and accepted. As a professional 3D scanner solution provider, ZG Technology’s product range includes 3D scanners as well as photogrammetry and portable CMM solutions. In this article, we will help you get started in understanding 3D measurement solutions and how ZG products can streamline your product development, NDT inspections, quality control processes and benefit your efficiency.

Here is the content list:

1. What is 3D measurement and where it's applied?

2. What 3D measurement solutions ZG Technology can offer?

3. A final word on ZG 3D measurement and scanner solutions

What is 3D measurement and where it’s applied?

3D measurement is a metrology process that uses different types of measurement tools to collect surface data on physical objects, such as their shapes, textures, geometries, or colors, to construct digital 3D data with high-density point clouds or triangle meshes. These 3D data can be further processed and used for reverse engineering or quality control, archived for future digital references, brought back to the physical world using a 3D printer, included in technical documentation, and much more.

With the development of the manufacturing industry, to create high-quality products that meet certain standards and perform optimally over time, designers, product development teams, and quality control inspectors need to use 3D measurement solutions to properly assess an object in 3D.

By capturing all the physical measurements of an object in 3D, manufacturers can ensure that parts are designed properly to fit together, optimize designs and tolerances, improve engineering processes and tooling, and cut costs associated with scraps, product recalls, and production downtimes.

So what types of companies need to apply 3D measurement? To put it in a nutshell: any manufacturer that produces products can benefit from 3D measurements for their product development workflows and quality control processes. 3D measurement is used in many different industries, such as:

-Aerospace

-Transportation and automotive

-Consumer products

-Education

-Heavy industries

-Healthcare

-Heritage

-Oil and gas

-Hydropower

3D measurement also plays a crucial role in additive manufacturing, also known as 3D printing. 3D measurement solutions can speed up prototyping, as users don’t need to create physical prototypes from scratch.

What 3D measurement solutions ZG Technology can offer?

The traditional 3D measurement solutions are represented by contact measurement tools that collect the object surface’s 3D data through physical contact, such as coordinate measuring machines (CMMs), articulated arms, and basic tools like calipers, gauges, etc. While there are many disadvantages of these approaches.

The contact measurement solutions collect the object’s surface data point by point, to collect enough points for good quality measurement can be time-consuming; When measuring soft or elastic objects, such as objects made of rubber or plastic, the object may deform even with little pressure from the contact measurement tool, which leads to imprecise measurement results; What’s more, these contact measurement solutions are dependent on users’ skills and efficiency, it can be difficult to train the right staff for complicated systems like CMM.

On the contrary, 3D scanners are non-contact measurement solutions which can capture the shape, geometries, textures, and colors of objects without physical contact, overcoming all of these challenges thanks to their unbeatable performance in terms of measurement speed and portability as well as data accuracy and reliability.

Here are some of the best 3D scanner and measurement solutions offered by ZG Technology:

Handheld 3D Laser Scanners

MarvelScan Tracker Free Marker Free Handheld 3D Laser Scanner AtlaScan High Precision Hole Flash Capture Handheld 3D Laser Scanner

The handheld 3D laser scanners project multiple laser lines upon the object being scanned, the laser lines will deform with the shape of the object. When scanning, the cameras take the laser line's specific shape and calculate the spatial information based on the triangulation principle. The scanner’s position in space is determined based on the relative position to positioning markers (small stickers provided with the system that can be placed directly on the part) on the object surface, AtlaScan, RigelScan and ZGScan series are good examples of handheld 3D laser scanners from ZG Technology.

Besides the 3D Scanner models applying the markers-positioning method, ZG Technology developed MarvelScan, the first Tracker-free and Marker-free portabl 3D laser scanner in the world. Thanks to the unique Inside-Out monocular positioning technology, during the whole scanning procedure of MarvelScan, the operator does not need to place sticker markers on the object at all, which improves portability and simplifies the calibration procedure dramatically.

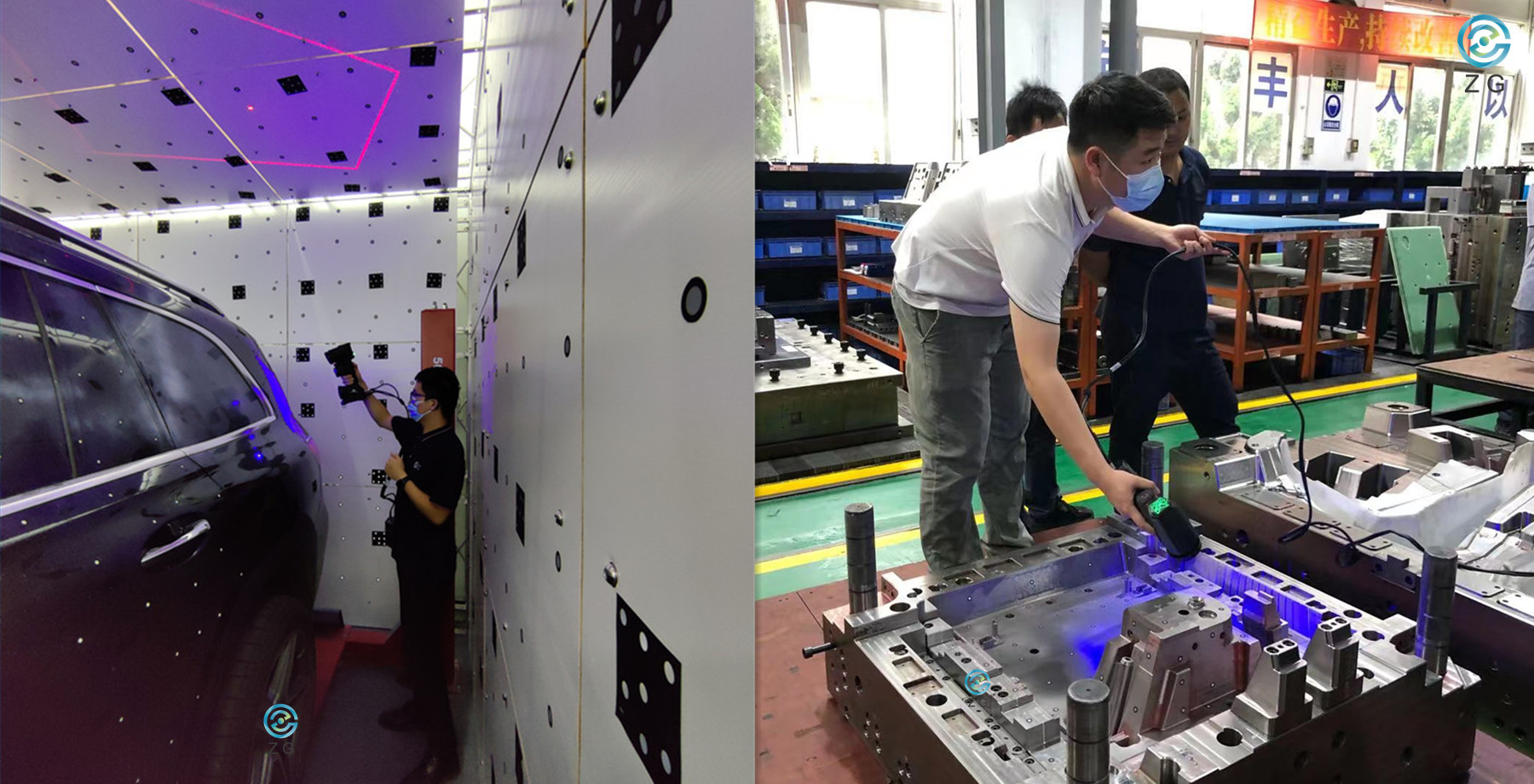

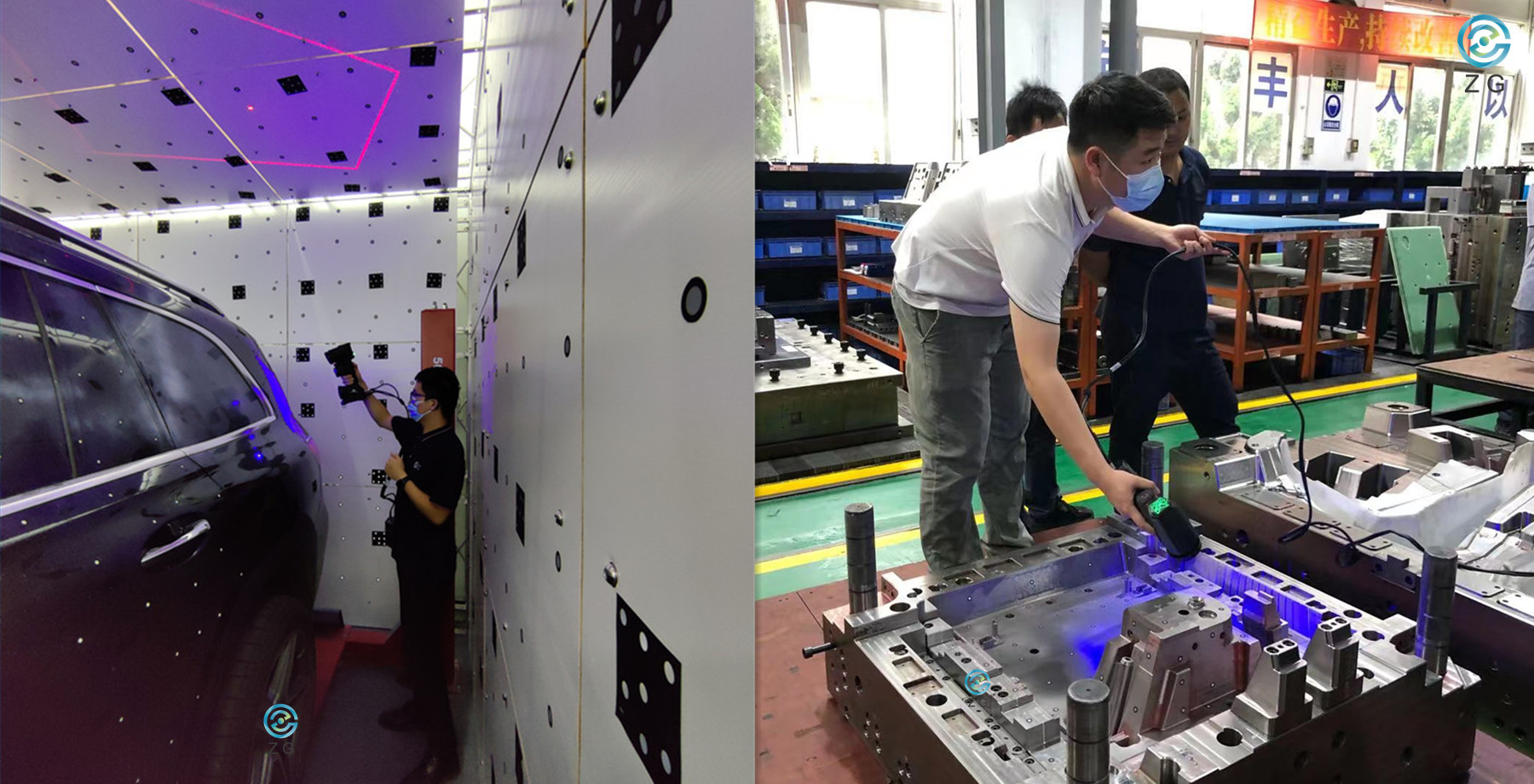

Optical Tracking 3D Laser Scanners

HyperScan Series Smart Optical Tracking 3D Laser Scanners

The hardware of the optical 3D scanner system is composed of an optical tracker and a handheld 3D laser scanner with a rigid structure marker frame. During the scanning process, the optical tracker will track the markers on the scanner and to establish the scanner’s position in the space. Thus there is no need to place positioning markers on the measured workpiece, which not only improves the convenience of operating the handheld scanner but also truly realizes instant scanning at the scanning site. The HyperScan series smart optical tracking 3D scanner from ZG Technology does not have high requirements for working conditions and spatial location of the workpiece, the workpiece can be scanned and inspected directly on the processing line.

Structured Light (White Light) 3D scanners

GScan Smart Full-color 3D Scanner

Structured-light (or white-light) scanners project light and shade patterns on the object being scanned. The cameras of the scanner detect variations in the pattern and rely on the geometry and texture (color) of the object to position the data. Several images must be acquired from various positions until the mesh is complete.

Interested in learning more about white light 3D scanners? Make sure you check out ZG’s smart full-color 3D Scanner GScan.

Photogrammetry

PhotoShot Lite Photogrammetry System Working With AtlaScan 3D Scanner

Photogrammetry technology uses encode markers and stitches multiple images of an object in different positions. The photogrammetry system then triangulates the points in the images to determine the location of them in a three-dimensional space.

For ZG 3D measurement solutions, photogrammetry systems are used together with 3D scanners to generate exceptionally accurate and repeatable 3D scan data for large-size objects very quickly. Make sure you don’t miss our Photoshot Lite blue light photogrammetry system with high volumetric accuracy for 3D scanning.

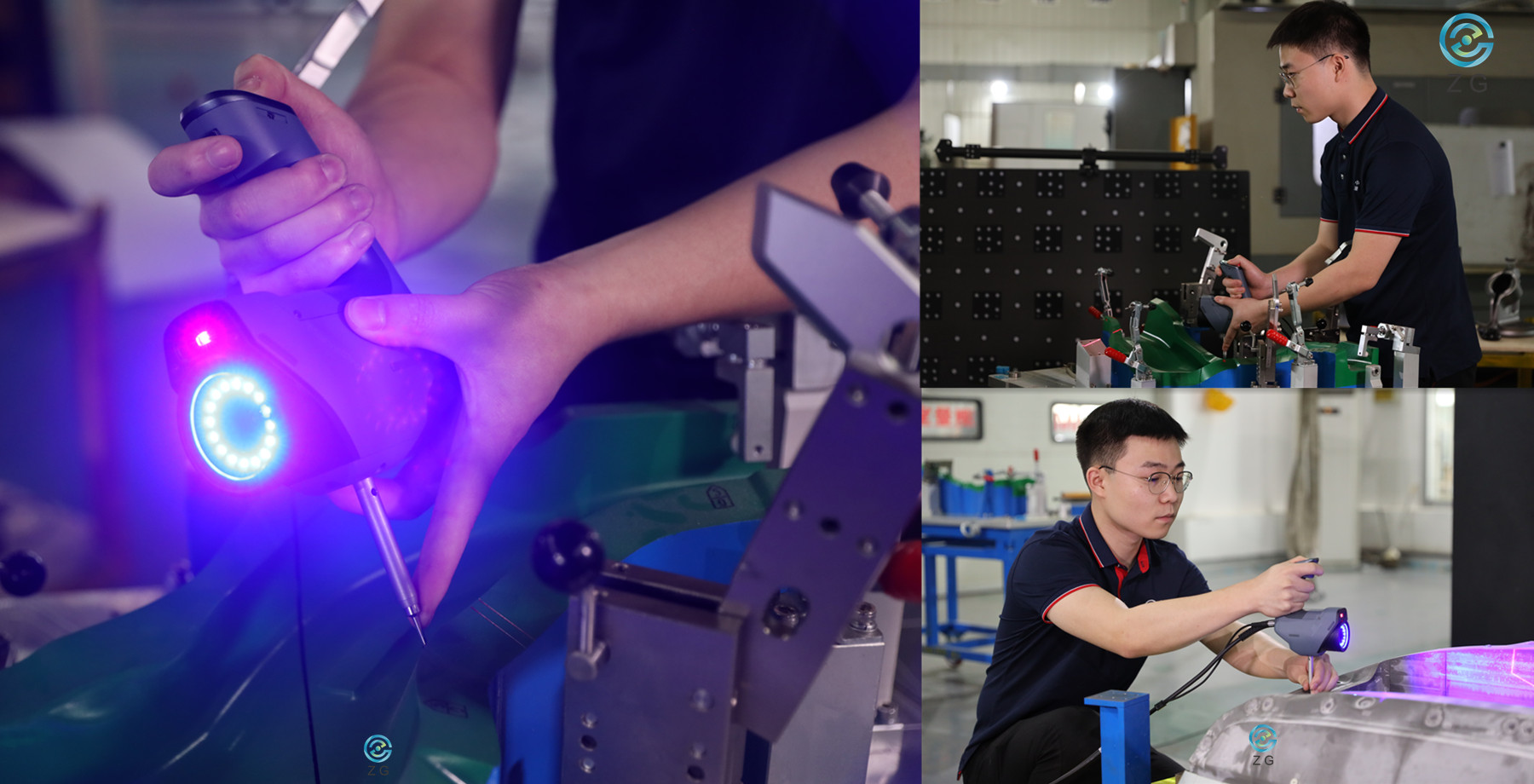

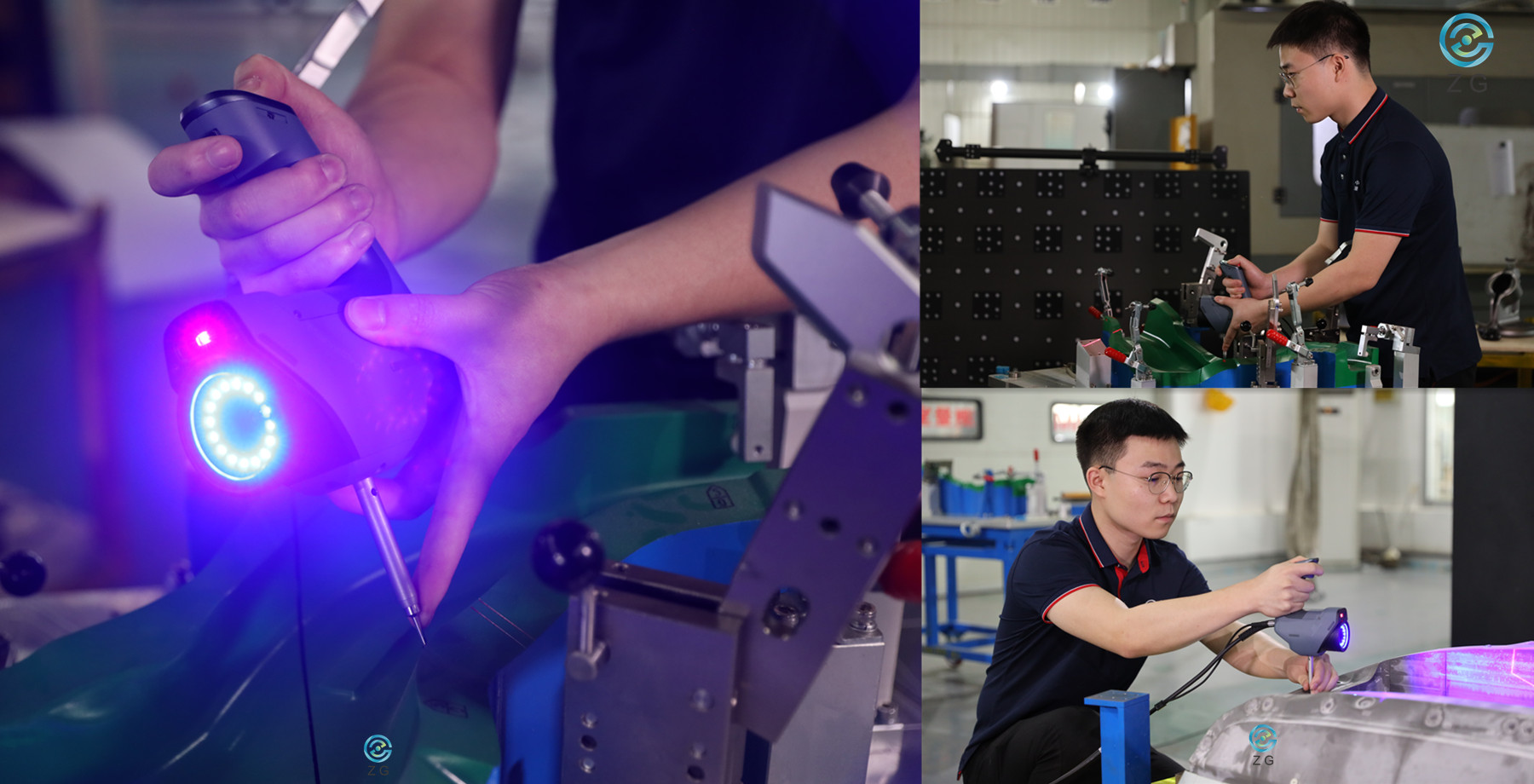

Portable Reverse Positioning CMM

MarvelProbe Reverse Positioning CMM for Probing Measurement

Contact-based handheld 3D solutions like articulated arms, or called portable measuring arms, probe the surface of an object physically and generate the 3D data based on Encoders. During the probing process, the articulated arms need to be fixed on a surface, which means they are very sensitive to vibrations and other environmental factors that can affect the data quality. Meanwhile, they also lack flexibility in terms of the locations in which they can be used and the size of objects they can measure due to the arm length limit.

MarvelProbe, portable reverse-positioning CMM self-developed by ZG Technology, does integrate photogrammetry functionality into the probe-contact measurement. This does not only improve the volumetric accuracy of the handheld scanners in large scenarios, but also provides a new flexible & portable measurement for mold production, fixture gauge, and installation adjustment without the limit of physical arms. Please check https://www.3d-zg.com/MarvelProbe-Portable-Reverse-positioning-CMM-for-Metrology-grade-Measurement-pd43697683.html for more information about MarvelProbe.

3. A final word on ZG 3D measurement and scanner solutions

As you can see, ZG 3D measurement solutions are a definitive game-changer in 3D measurement industry. ZG 3D scanners can increase the overall quality and performance reliability of products. They can also reduce product development and inspection times so that products can hit the market sooner. And in the era of Industry 4.0, 3D measurement tools on robot-mounted systems are an invaluable configuration that can be incorporated within a manufacturer’s path to automated quality control. For more information about ZG 3D measurement solutions or cooperation demands, please contact us freely.