The advent of 3D scanning technology has revolutionized industries by providing the ability to capture complex shapes and objects with remarkable precision. While 3D scanning was initially used mainly for prototyping and design verification, its applications have expanded significantly, becoming a core tool in production and reverse engineering. Professional 3D scanners are now at the heart of modern manufacturing workflows, enabling faster production cycles, improving accuracy, and reducing costs. ZG Technology, a leader in metrology-grade 3D scanning solutions, offers innovative scanners that empower industries to not only create prototypes but also streamline production processes and enhance reverse engineering capabilities.

How Professional 3D Scanners Enable Advanced Production Workflows

Professional 3D scanners have made a significant impact on production workflows by providing precision, speed, and repeatability. From initial prototype creation to mass production, the ability to scan parts quickly and accurately is essential for ensuring consistency and quality across a product line.

From Prototyping to Mass Production: Data Precision and Repeatability

In the past, manufacturers relied on manual measurements and hand tools to validate prototypes. These methods were often time-consuming and prone to errors. However, professional 3D scanners offer an automated solution that captures highly detailed, micron-level data, enabling manufacturers to ensure that their products meet the required specifications from the outset. The use of 3D scanning in production provides more accurate measurements and greater repeatability, which is crucial for mass production.

By scanning prototypes and comparing them to the digital design model, manufacturers can quickly identify any discrepancies in dimensions or geometry. This immediate feedback allows for rapid adjustments, reducing the time spent on rework and ensuring that products are produced to the highest standards.

Automation, Inspection, and Assembly Verification

3D scanning plays a vital role in automating the inspection process. With the ability to scan entire assemblies in a single pass, professional 3D scanners can detect issues such as misalignment, warping, or defects in real-time. This is particularly beneficial in industries like automotive manufacturing, where parts need to fit together perfectly to ensure the quality and safety of the end product.

Moreover, 3D scanning is instrumental in verifying assembly processes. Manufacturers can scan finished products to confirm that they align with the CAD models, ensuring that the assembly process is completed correctly every time. This automated inspection reduces the need for manual checks, saving time and resources, while also ensuring that products are assembled to the highest precision.

Reverse Engineering: From Object to Digital Twin

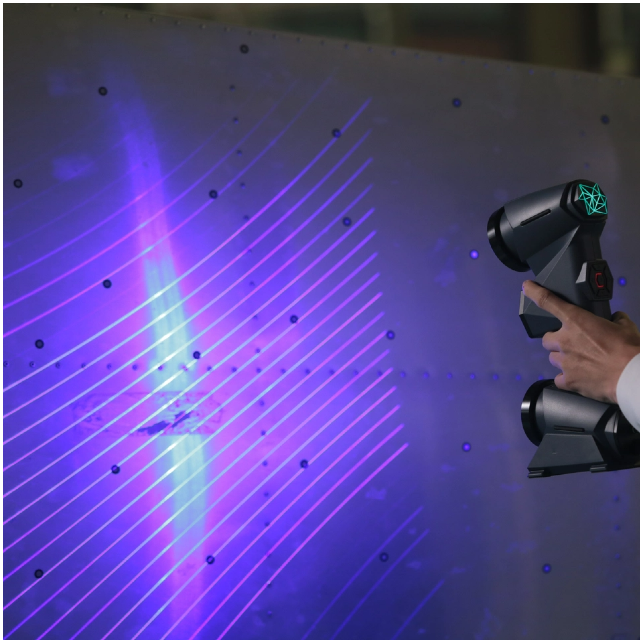

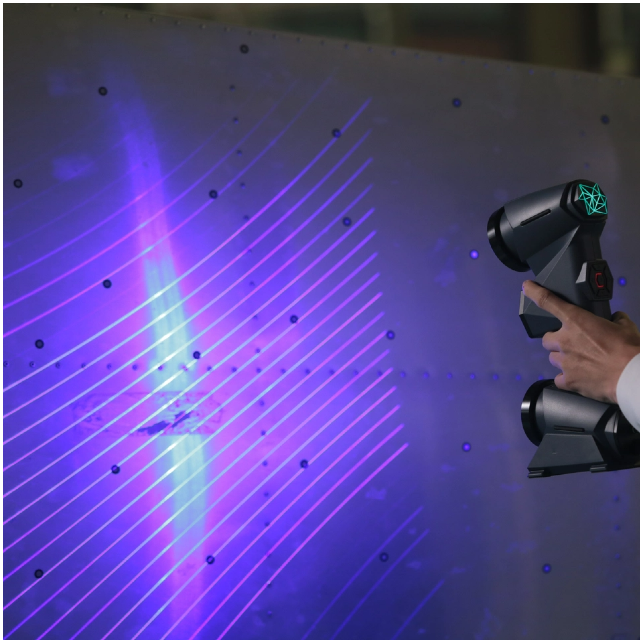

One of the most powerful applications of professional 3D scanners is in reverse engineering. Reverse engineering involves taking a physical object and creating a digital replica, often referred to as a digital twin, for analysis, redesign, or reproduction. This process has a wide range of applications, from repairing outdated parts to creating new designs based on existing products.

The Reverse Engineering Process: Scan → Point Cloud → Mesh → CAD Reconstruction

The reverse engineering workflow begins with scanning an object to capture its shape and features. The 3D scanner creates a detailed point cloud, which represents the surface geometry of the object. This data is then processed into a mesh, which forms the basis for creating a CAD model. Using the scanned data, designers and engineers can accurately reproduce parts, modify existing designs, or perform structural analysis to improve product performance.

The use of professional 3D scanners in reverse engineering significantly reduces the time it takes to create a digital model from a physical object. The precision offered by ZG Technology’s scanners ensures that the digital replica is as close to the original as possible, allowing for accurate modifications and design improvements.

Speeding Up Development Cycles

One of the major advantages of using 3D scanning in reverse engineering is the ability to accelerate development cycles. Without the need to rely on blueprints or manual measurements, engineers can quickly digitize a physical object, analyze its design, and make improvements. This drastically shortens the time needed for product development, particularly in industries like automotive and aerospace, where components must be meticulously designed and tested before production.

By leveraging professional 3D scanners, companies can not only replicate old or outdated parts but also innovate and redesign components more efficiently. The time saved in the scanning and modeling stages allows for quicker iteration and testing, leading to faster product releases.

Use Cases: Production Improvement Through Reverse Engineering

Reverse engineering is particularly beneficial when dealing with parts that no longer have CAD data or for improving existing designs. The following use cases highlight the power of 3D scanning and reverse engineering across various industries:

Rebuilding Parts Without Original CAD Data

In industries such as automotive and aerospace, it’s common to encounter parts that were manufactured long ago, with no digital record available. Professional 3D scanners allow manufacturers to scan these physical parts and create a digital model that can be used for remanufacturing or improvement.

For example, in the automotive industry, older car models or rare components might need to be reproduced. ZG Technology’s 3D scanners can capture the exact geometry of the original part, enabling engineers to create a CAD model for modern manufacturing processes. This eliminates the need for manual measurements, reducing errors and speeding up the production of replacement parts.

Customizing and Improving Complex Machinery Parts

Another significant use case for 3D scanning in reverse engineering is the customization and improvement of complex machinery parts. Manufacturers often need to modify or enhance existing components to improve efficiency, durability, or performance. By scanning the original part, engineers can analyze its design, identify areas for improvement, and develop a more efficient version without starting from scratch.

For instance, in the aerospace industry, components such as turbine blades or engine parts undergo continuous improvement. ZG Technology’s 3D scanners provide the precision necessary to capture the fine details of these parts, enabling engineers to enhance their designs and ensure better performance.

Real-World Industry Examples: Automotive, Aerospace, and Equipment Maintenance

Real-world examples highlight the value of professional 3D scanners in reverse engineering:

Automotive: Manufacturers use 3D scanning to reverse engineer car parts, from engine components to body panels, ensuring that they meet exact specifications for both performance and safety.

Aerospace: Reverse engineering is essential in the aerospace industry for improving the design of critical components such as aircraft turbines and landing gear. 3D scanning ensures that parts are replicated with the utmost precision, reducing the risk of failure and improving safety.

Equipment Maintenance: Heavy machinery used in industries like mining and construction often requires parts that are no longer available. 3D scanning helps maintain these machines by reverse engineering replacement parts and ensuring that they function properly within the existing systems.

Software and Workflow Considerations for Reverse Engineering

When using professional 3D scanners for reverse engineering, it is important to understand how the scanning data is processed and integrated into the workflow.

Handling Point Clouds and Creating Models

The first step in the reverse engineering process is capturing the point cloud data from the 3D scan. Advanced software is then used to convert this point cloud into a mesh, which is the foundational 3D model. From there, the mesh can be used to create CAD models that can be used for design, analysis, or manufacturing.

The software used for reverse engineering must be capable of accurately processing point cloud data and converting it into usable models. ZG Technology’s scanners come with powerful software tools that can handle large datasets, ensure accuracy, and seamlessly integrate with existing CAD platforms.

Data Integration with CAD Platforms

For effective reverse engineering, it is crucial that the scanned data can be integrated directly into CAD software. This ensures that engineers can immediately begin modifying or improving the design based on the scanned data. The integration process should be seamless, allowing the scanned data to be easily aligned with existing CAD files and used for further design work.

Benefits of Professional 3D Scanners Over Traditional Methods

Compared to traditional methods like manual measurements or contact-based inspection, professional 3D scanners offer numerous benefits, particularly in terms of precision, speed, and product consistency.

Enhanced Precision and Speed

3D scanners provide a level of precision that far exceeds traditional methods. The ability to measure complex geometries with micron-level accuracy allows for the creation of highly detailed models, which is especially valuable in industries that demand the highest level of quality.

In addition to precision, 3D scanning is also significantly faster than traditional methods. What would take hours or days using manual measurements can now be done in a matter of minutes, accelerating the design, inspection, and production cycles.

Reducing Human Error and Repetitive Processes

Another key benefit of 3D scanning is its ability to reduce human error. With traditional measurement methods, the chances of mistakes increase as the complexity of the part grows. 3D scanning eliminates this risk by capturing data automatically and accurately.

Additionally, the automation of the scanning and inspection process reduces the need for repetitive manual tasks, saving time and labor costs while increasing productivity.

Conclusion

Professional 3D scanners have become indispensable tools in modern manufacturing, enabling faster, more accurate production processes and enhancing reverse engineering capabilities. By capturing detailed data and creating digital models with micron-level precision, reverse engineering 3D scanners empower businesses to innovate, reduce development time, and improve product quality. Whether in automotive, aerospace, or equipment maintenance, the use of 3D scanning technology is essential for staying competitive in today’s fast-paced industrial environment.

For more information on how ZG Technology’s professional 3D scanners can streamline your production and reverse engineering workflows, contact us today. Let us help you enhance your manufacturing process and bring your designs to life with unparalleled precision.

FAQ

What is reverse engineering in 3D scanning?

Reverse engineering involves scanning a physical object to create a digital model, which can then be analyzed, modified, or reproduced.

How do professional 3D scanners improve production workflows?

Professional 3D scanners enhance production workflows by automating inspections, improving precision, and reducing production time.

What industries benefit from using professional 3D scanners for reverse engineering?

Industries like automotive, aerospace, and equipment maintenance benefit from 3D scanning to reproduce and improve parts with high precision.

What is the role of software in reverse engineering with 3D scanners?

Software is used to process point cloud data captured by the 3D scanner, converting it into usable 3D models for analysis, design, or manufacturing.