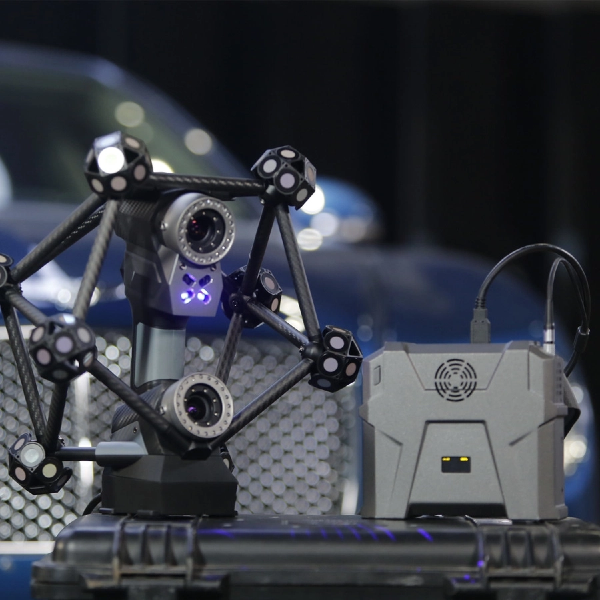

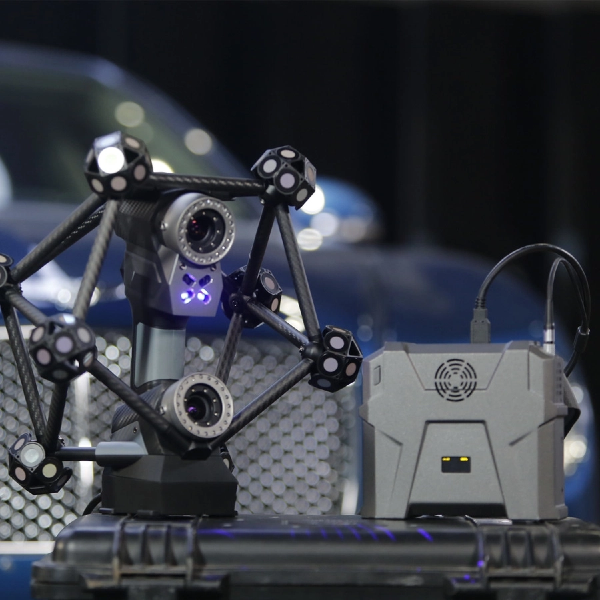

Introduction to Wireless 3D Scanners

A wireless 3D scanner is an innovative device that captures the geometry of physical objects and converts them into precise digital 3D models. Unlike traditional scanners that rely on cables, a wireless 3D scanner eliminates the limitations of wires, allowing users to scan objects with greater mobility and efficiency. This shift is especially valuable for industries where flexibility, speed, and real-time collaboration are essential.

Wireless technology in 3D scanning is not just about convenience—it represents a major leap in how data is captured, processed, and shared. With high accuracy, real-time transmission, and compatibility with cloud-based platforms, these devices are revolutionizing sectors like manufacturing, healthcare, and cultural heritage preservation. For businesses seeking to adopt Industry 4.0 practices, wireless scanning is often the entry point to a more connected and intelligent workflow.

In addition, wireless scanners support decentralized work environments. For example, a manufacturing plant in one location can capture component data and instantly transmit it to design engineers overseas, speeding up decision-making and reducing costly downtime.

How a Wireless 3D Scanner Works

Optical Principles

Most wireless 3D scanners use structured blue light or laser triangulation to capture surface details. By projecting patterns of light and recording distortions with sensors, the scanner calculates the precise shape of an object. In some advanced scanners, hybrid technologies are used to combine the benefits of laser accuracy with structured light’s ability to capture color and texture.

Wireless Data Transmission

Instead of tethered cables, data is transmitted wirelessly—via Wi-Fi, Bluetooth, or 5G networks—directly to a computer, tablet, or cloud platform. This eliminates clutter and speeds up workflows. For high-volume industries, wireless transmission also enables continuous scanning of production lines, where data is instantly shared with quality management systems.

Battery and Portability

A key feature of a wireless 3D scanner is its battery-powered mobility. Users can operate it in remote areas, factories, or medical facilities without worrying about power outlets or tangled cables. Newer models feature quick-swap batteries, allowing uninterrupted scanning for extended projects such as large-scale construction surveys.

Software Integration

The hardware is only half of the system. Advanced 3D scanning software ensures that captured data is aligned, processed, and transformed into usable formats such as STL, OBJ, or CAD files. Some solutions also provide automated mesh repair, texture mapping, and AI-based error detection, minimizing manual editing and accelerating the workflow from scan to final model.

Key Features of a Wireless 3D Scanner

A reliable wireless 3D scanner should provide more than mobility. Below are the core features buyers should evaluate:

Feature | Importance | What to Look For |

Accuracy and Resolution | Ensures high-quality 3D models for inspection or design. | Accuracy within 0.02–0.1 mm; resolution based on application needs. |

Scanning Speed and Range | Determines productivity and suitability for small or large objects. | Speeds over 1,000,000 points per second; range from handheld to long-distance. |

Battery Life | Supports uninterrupted scanning sessions. | At least 2–4 hours of continuous use; fast-charging options. |

Data Transmission | Provides stable, fast connectivity. | Wi-Fi 6, Bluetooth 5.0, or 5G compatibility. |

Software Compatibility | Ensures seamless data handling. | Integration with CAD, inspection, or reverse engineering software. |

Portability and Ergonomics | Improves usability for fieldwork and factory floors. | Lightweight designs under 1.5 kg, user-friendly interface. |

Beyond these technical benchmarks, users should also consider data security. With wireless transmission, encryption protocols and secure cloud access are essential to protect sensitive industrial designs or patient medical records.

Advantages of Using a Wireless 3D Scanner

Increased Flexibility

Without cables, operators can move freely around large objects, vehicles, or machinery. This is especially useful in aerospace or automotive sectors, where objects may be too big or heavy to move to a scanning station.

Reduced Setup Time

A wireless 3D scanner requires minimal setup. No cable management means faster scanning, whether in workshops, hospitals, or outdoor sites. Field engineers can carry the scanner into construction zones, reducing downtime and making scanning possible even in rugged environments.

Higher Productivity

Mobility allows multiple scans in different environments within a short timeframe, accelerating prototyping and inspection processes. Combined with real-time wireless transfer, engineers can identify design flaws immediately instead of waiting for batch processing.

Enhanced Collaboration

Data captured by a wireless 3D scanner can be instantly transmitted to cloud servers, making it easier for teams across locations to collaborate. For instance, a cultural heritage project can involve archaeologists in the field, historians at a university, and 3D artists creating virtual exhibits—all working from the same scanned dataset.

Applications of Wireless 3D Scanners in Different Industries

Manufacturing and Quality Control

In manufacturing, a wireless 3D scanner enables fast inspection of components, ensuring products meet design tolerances. It also helps in reverse engineering by creating CAD-ready models of legacy parts. Factories adopting lean manufacturing methods rely on these scanners to eliminate bottlenecks and maintain production quality.

Aerospace and Automotive

Engineers use wireless 3D scanners to evaluate aerodynamic components, detect surface flaws, and validate assemblies without needing to transport heavy objects. For prototype vehicles, wireless scanning accelerates the design iteration cycle, allowing rapid adjustments to body panels or engine parts.

Healthcare and Dentistry

From custom prosthetics to dental implants, wireless 3D scanners ensure precision fitting while improving patient comfort during the scanning process. Clinics benefit from portability, as doctors can scan patients directly at their bedside instead of moving them to a lab.

Cultural Heritage Preservation

Museums and archaeologists rely on wireless scanners to digitally archive fragile artifacts and monuments without physically moving them. For example, entire archaeological sites can be captured for VR tours, ensuring preservation even if physical structures degrade over time.

Architecture and Construction

Wireless 3D scanners provide accurate as-built data, helping architects design digital twins of buildings and track structural changes. Contractors use them to verify work against blueprints, reducing costly rework and project delays.

Wireless 3D Scanner vs. Traditional 3D Scanner

A side-by-side comparison reveals why wireless technology is increasingly preferred:

Criteria | Wireless 3D Scanner | Traditional 3D Scanner |

Mobility | Highly portable, no cables required | Restricted by cables and power sources |

Setup Time | Minimal, plug-and-play | Requires more preparation and cable setup |

Accuracy | Comparable with advanced models | High accuracy, but less convenient |

Usability | Ideal for on-site and fieldwork | Better suited for fixed environments |

Cost | Slightly higher due to wireless tech | More affordable but less flexible |

Collaboration | Cloud-ready and remote access | Limited to local systems |

While traditional scanners remain valuable for ultra-high-precision laboratory settings, wireless 3D scanners are closing the gap quickly, making them a better investment for businesses seeking balance between accuracy and efficiency.

How to Choose the Right Wireless 3D Scanner

Define Your Application

Consider whether the scanner will be used for industrial inspection, healthcare, or cultural documentation. Applications determine whether you need high accuracy, portability, or advanced texture capture.

Evaluate Technical Specs

Focus on accuracy, resolution, scanning speed, and range. For example, dental labs prioritize micron-level accuracy, while construction sites prioritize range and durability.

Assess Software Ecosystem

Choose a wireless 3D scanner that integrates with your existing CAD/CAM, inspection, or design software. Software that automates alignment and supports cloud collaboration will deliver the best ROI.

Consider After-Sales Support

Technical support, training, and warranty services play a crucial role in ensuring long-term value. Some providers also offer periodic software updates that extend hardware lifespan, making your investment future-proof.

Best Practices for Using a Wireless 3D Scanner

Preparing the Object

Clean the object surface to avoid reflective interference. For glossy materials, apply a matte spray for better capture. Consistency in preparation ensures fewer rescans and higher efficiency.

Optimizing Environment

Avoid strong sunlight or uneven lighting. Indoor environments with controlled lighting yield the best results. For outdoor scans, portable light diffusers or tents can help create stable conditions.

Scanning Techniques

Move the wireless 3D scanner smoothly around the object. Maintain consistent distance and angle for uniform data capture. For large objects, divide the scan into multiple sections and merge them using alignment software.

Data Processing

Use the scanner’s software to align multiple scans, remove noise, and generate watertight meshes. Many platforms also allow direct export to 3D printing, VR/AR applications, or engineering analysis tools, extending the value of each scan.

The Future of Wireless 3D Scanners

AI and Automation

Future scanners will integrate AI algorithms that automatically detect errors and suggest corrections in real time. Automated workflows will minimize the need for manual intervention, making scanning accessible even to non-experts.

5G Connectivity

With 5G, wireless 3D scanners will transmit massive data sets almost instantly, supporting remote collaboration in industries like telemedicine. Doctors may eventually scan patients in one country while specialists review the 3D models live from another.

AR/VR Integration

Scanned models will directly feed into augmented reality (AR) and virtual reality (VR) platforms, enhancing training and immersive design experiences. This is particularly relevant for education, where students can interact with 3D replicas of machinery, anatomy, or cultural artifacts.

Miniaturization and Wearables

Smaller, lightweight wireless 3D scanners or wearable scanning devices will emerge, making 3D capture as easy as using a smartphone. Imagine engineers wearing smart glasses that capture environments in 3D while they work hands-free.

Conclusion

The wireless 3D scanner is no longer just a convenient upgrade—it has become a transformative technology driving innovation across industries. From manufacturing and aerospace to healthcare and cultural heritage preservation, its advantages in mobility, precision, and real-time collaboration make it an essential tool for modern workflows.

For companies moving toward Industry 4.0 and digital transformation, adopting a wireless 3D scanner is a strategic investment. It boosts productivity, reduces operational costs, and supports a future-ready approach to design, inspection, and data management.

Among global solution providers, ZG Technology Co., Ltd. stands out with its professional-grade wireless 3D scanners that combine accuracy, portability, and powerful software integration. Their solutions are designed to meet the diverse needs of industries worldwide, from rapid prototyping and reverse engineering to medical applications and large-scale scanning projects.

If you are exploring ways to enhance your operations with advanced 3D scanning technology, we highly recommend learning more about ZG Technology’s expertise. You can reach out to their team for tailored advice and discover how their innovative solutions can help your business achieve the next level of digital success.