Backstory

Heavy industries and mining usually mean difficult conditions and oversized equipment, quality inspection plays a vital role to guarantee the equipment's stability and durability under harsh working environments. Considering the equipment size and complexity, it's usually the measurement tool that needs to come to the part, and not the opposite. The engineers are required to measure all the dimensions of the equipment, and the possible interferences between different subassemblies, which means the measuring data not only has to be precise to inspect the subassemblies'dimensional specifications, but also has to be as complete as possible to check if different subassemblies can be in good fit for optimal performance.

That was the challenge posed to ZG Technology by a heavy steel plate and mining equipment manufacturer in China. To control the quality of the mining equipment in advance, their overseas customer requires them to provide the 3D digital data and comprehensive inspection reports of mining equipment before delivery. By doing this, their customer can compare the 3D data with their original model and archived data to verify the quality. This is the first time they are required to do so; In the past, the manufacturer used to take measurements with traditional measurement tools like tape measures and gauges, which took days of manual labor. With a tight schedule before delivery date, completing the 3D data capturing and comprehensive inspection reports appears to be a mission impossible. Mr. Hu, a Drafting Technician, is the man doing the measuring.

The Challenge

The parts Mr. Hu and his team used to measure and inspect were mainly heavy steel plates, using traditional measuring tools like measuring tape, calipers, gauges, etc. were workable. While mining equipment is their new product and it caused Mr. Hu some trouble. When measuring large parts that have compound curves and forms, traditional measurement tools become inadequate. The effort and inaccuracy of measuring and drawing by hand lead to a high risk of errors.“There is huge stress involved when I'm trying to do large equipment like this with the tools we used previously'' he said.

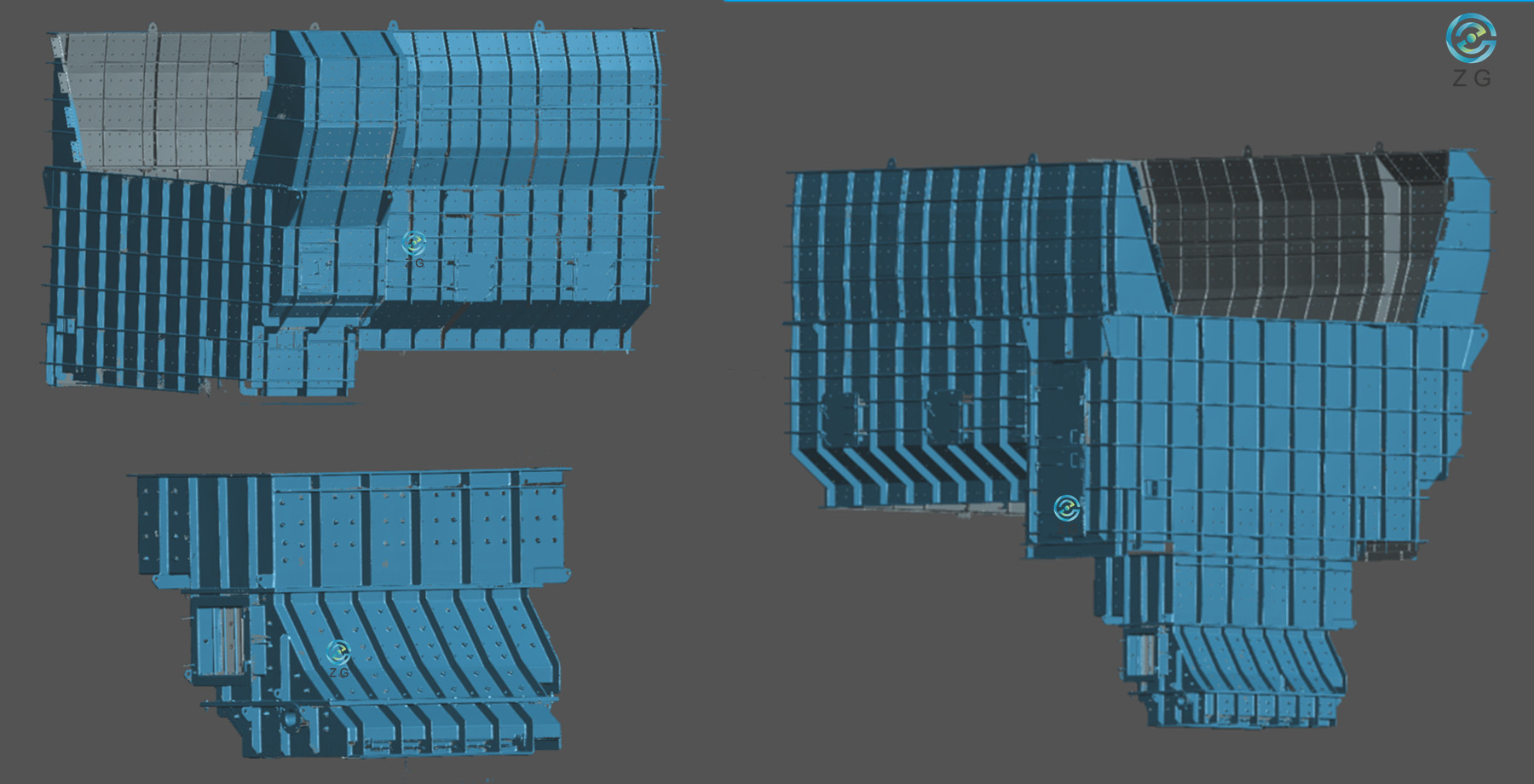

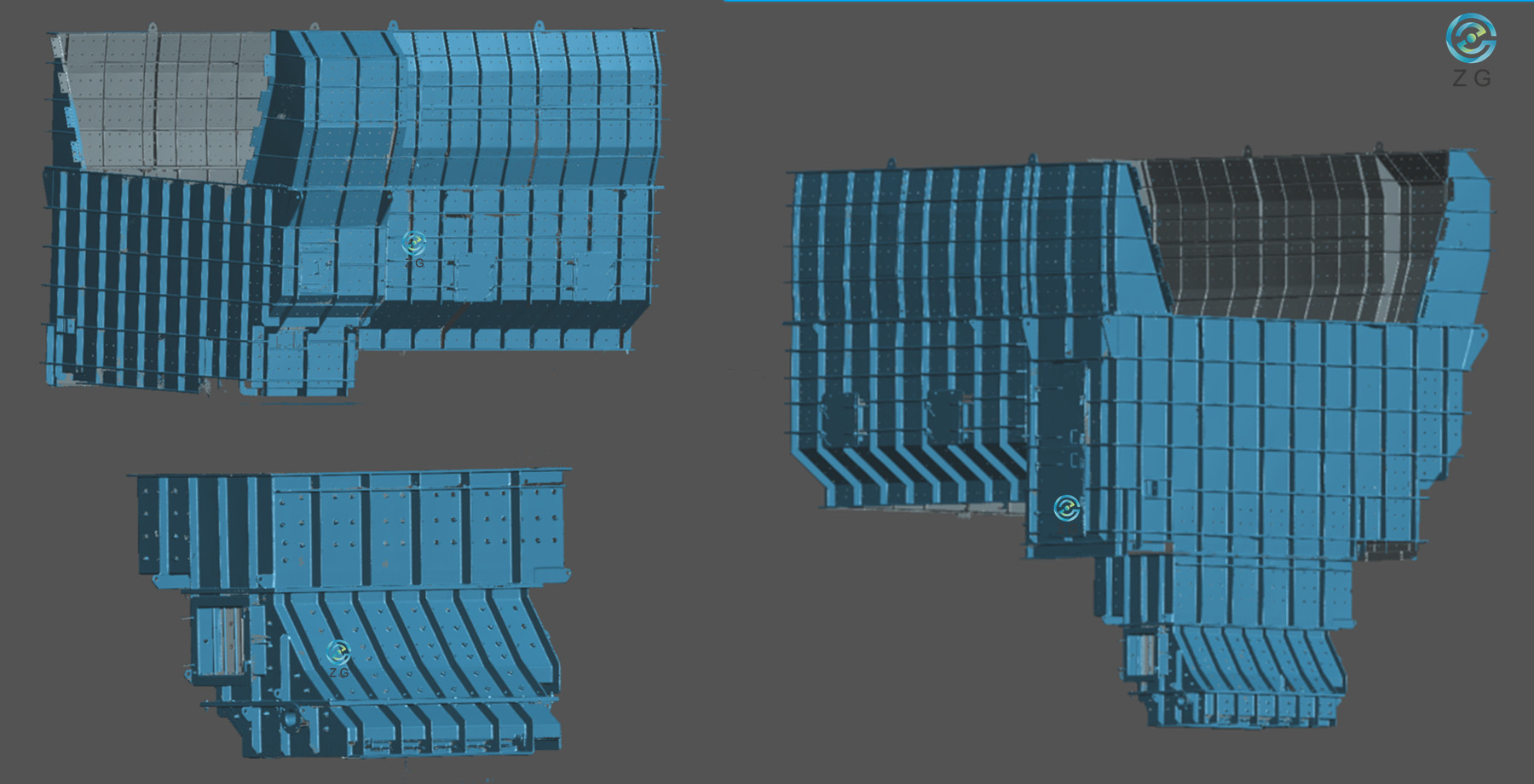

Furthermore, the whole line would have to stop to allow him to take measurements. And with the sheer size of the mining equipment consisting of two subassemblies, one is 8m x 6m x5m in dimension and the other one is 5m x 3m x2.5m, Mr. Hu couldn't do the work just by himself. He quickly realized there was a better, faster, and more accurate way to measure the mining equipment for inspection. They contacted ZG Technology to find a better solution for on-site measurement and inspection. As a leader in 3D measurement solutions, ZG helps to identify an optimal solution for this application. Using ZG smart handheld 3D scanner RigelScan Plus and Photogrammetry System PhotoShot Lite, the customer can successfully capture 3D data of the mining equipment and assemble it in 3rd party software for inspection within several hours, compared to several days required by the traditional method.

The Solution

1. Set Up PhotoShot Lite Photogrammetry System and Capture Markers Data

#1, To place encode markers, sticker markers, and scale bar properly on the mining equipment subassemblies;

#2, Use PhotoShot Lite photogrammetry system to take photos of the scale bar, encode markers and sticker markers;

#3, Post-process the markers data in ZG scanning software and save the data.

By taking photos of the scale bar, encoder markers, and sticker markers, the PhotoShot Lite photogrammetry system can triangulate the markers in the images to determine their location in a three-dimensional space. When the markers data is imported into ZG scanning software, it can help to constrain the scan data to generate exceptionally accurate and repeatable 3D data for large-size objects very quickly. When used with RigelScan Plus Smart Handheld Blue Laser 3D Scanner, the scanning volumetric accuracy is up to 0.02+0.020mm/m.

2. Import Markers Data and 3D Scan the Mining Equipment

#1, Connect RigelScan Plus with power and warm up the scanner for 20mins;

#2, Analyze how to scan the mining equipment subassemblies from different angles;

#3, Start to scan the mining equipment subassemblies;

#4, Save the data in project file for further processing.

The RigelScan Plus Smart Handheld Blue Laser 3D Scanner can capture fine features of the parts with an accuracy up to 0.02mm, certified by National Institute of Metrology. RigelScan Plus applies blue laser scanning technology for easy capturing of dark, shiny and refelective surfaces. In the mean time, RigelScan Plus can be equipped with ZG wireless module ZGFree Box II, for an easier and more flexible scanning experience of large parts.

3. Assemble the 3D Scan Data in 3rd Party Software for Measurement and Inspection

#1, To process the data in ZG Scanning software;

#2, To edit the data and delete extra data;

#3, To export the data in the format of .stl for the next evaluation;

#4, To assemble the 3D scan data in 3rd party software for measurement and inspection.

The Conclusion

ZG's 3D scanner and photogrammetry solution helps the client to reduce its inspection times from days to hours, not only saving significant time and money but also meeting its customer's requirements for assembly inspection, comprehensive reports, and lower risk of assembly issues after delivery. What's more, in addition to completing the quality inspection and ensuring smooth delivery of products, the 3D scan data can also be used for digital archiving. When the equipment needs further maintenance, repair or overhaul, the scan data can be used for guidance, greatly enhancing the accuracy and efficiency in the whole equipment life cycle.

When it comes to measuring oversized objects and creating 3D data for 3D modeling, reverse engineering, and quality inspection, the solution of ZG Smart Handheld 3D Laser Scanner and Photogrammetry System can get jobs done quickly and accurately. Due to its 100% portability, ZG handheld 3D Scanners can perform the acquisition directly on the production floor – and even directly in the field, on the most unstable grounds. Since the engineers need to inspect the correct assembly features and dimensions, the acquisition must be accurate and hold all the information needed to produce a functional part that will perfectly fit in the equipment's assembly. Compared to traditional measurement methods, the ZG portable 3D scanners and photogrammetry system can provide complete and accurate 3D data, dimensions are quickly measured and virtual assembly is easily available to the engineers. This makes ZG 3D portable 3D laser scanner and photogrammetry system the best 3D measurement solution for oversized mining equipment and large size objects, making the mission impossible in the past a reality.