Whether you’re buying your first 3D scanner or upgrading an existing one, there are many factors to consider before choosing the right 3D scanner for your application. In this article, we will discuss about the most important things to consider before making the decision and help you to choose the most suitable 3D scanner.

Ask Yourself

1. Why do you need a 3D scanner?

This is the most important question to be answered first. There are many reasons why you need a 3D scanner because it’s much more accurate and efficient than the traditional measuring methods. You can use it to save time on the design stage, to make the prototype process faster, or use it for reverse engineering, better quality control, etc.

2. What is the size of the object to be scanned?

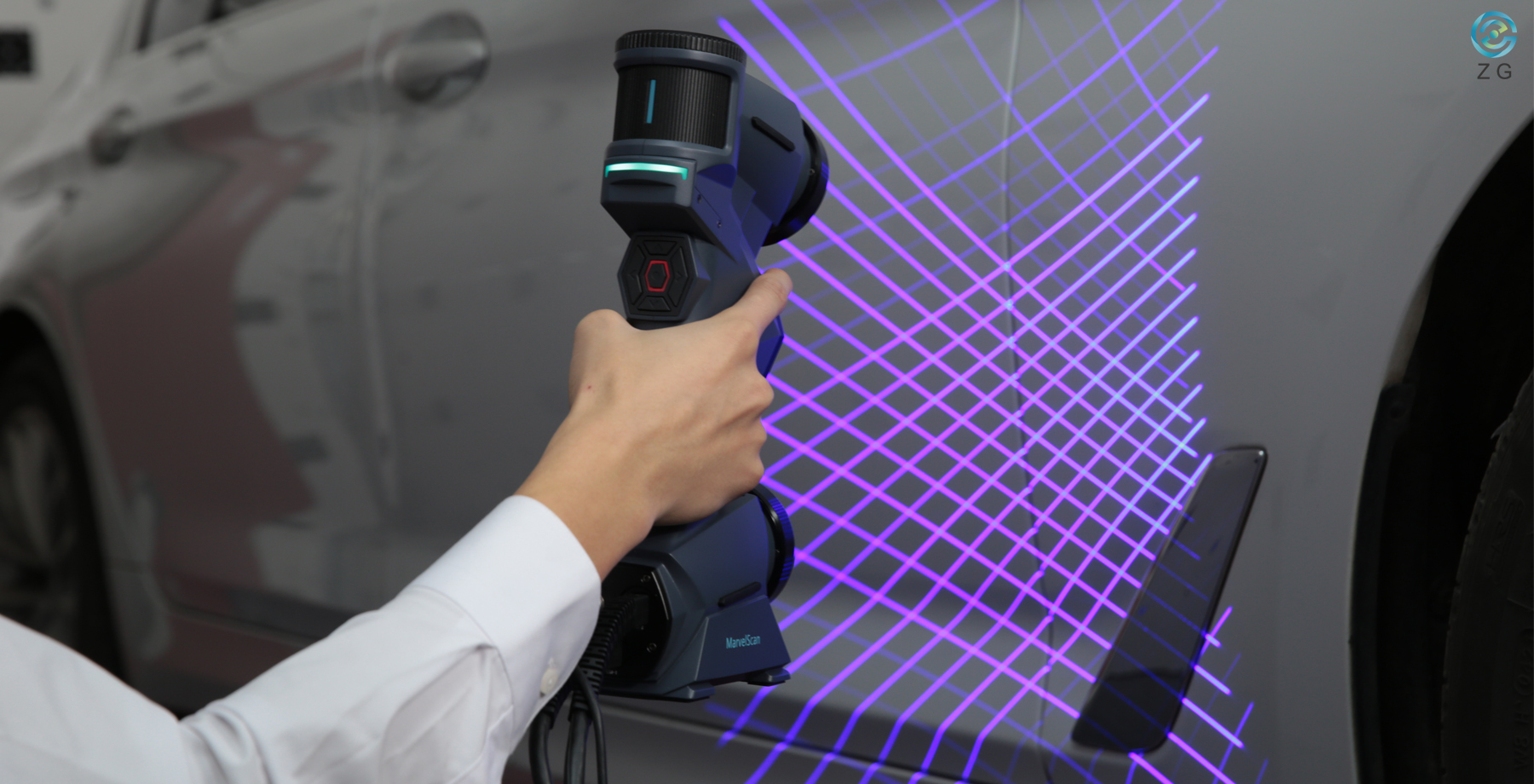

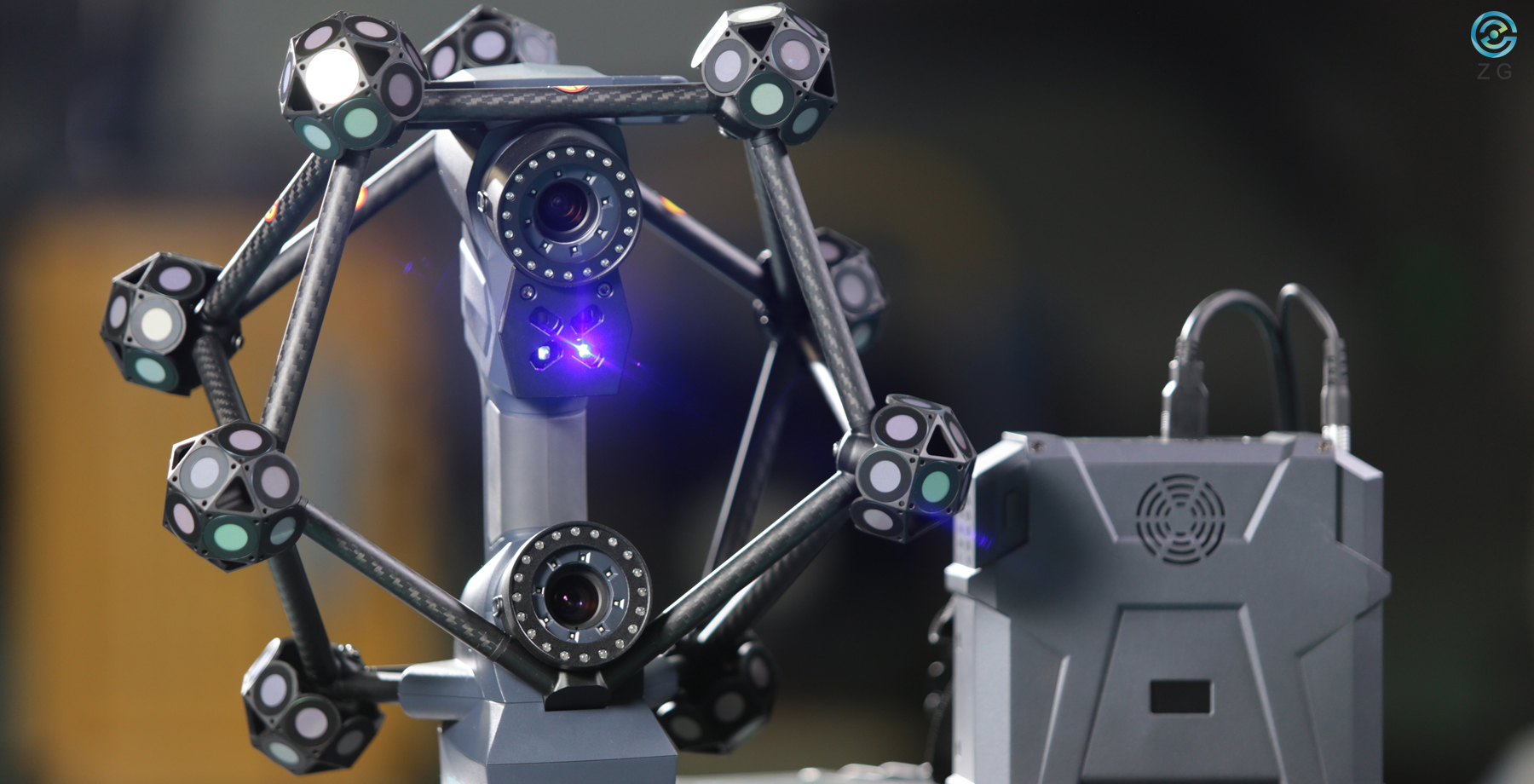

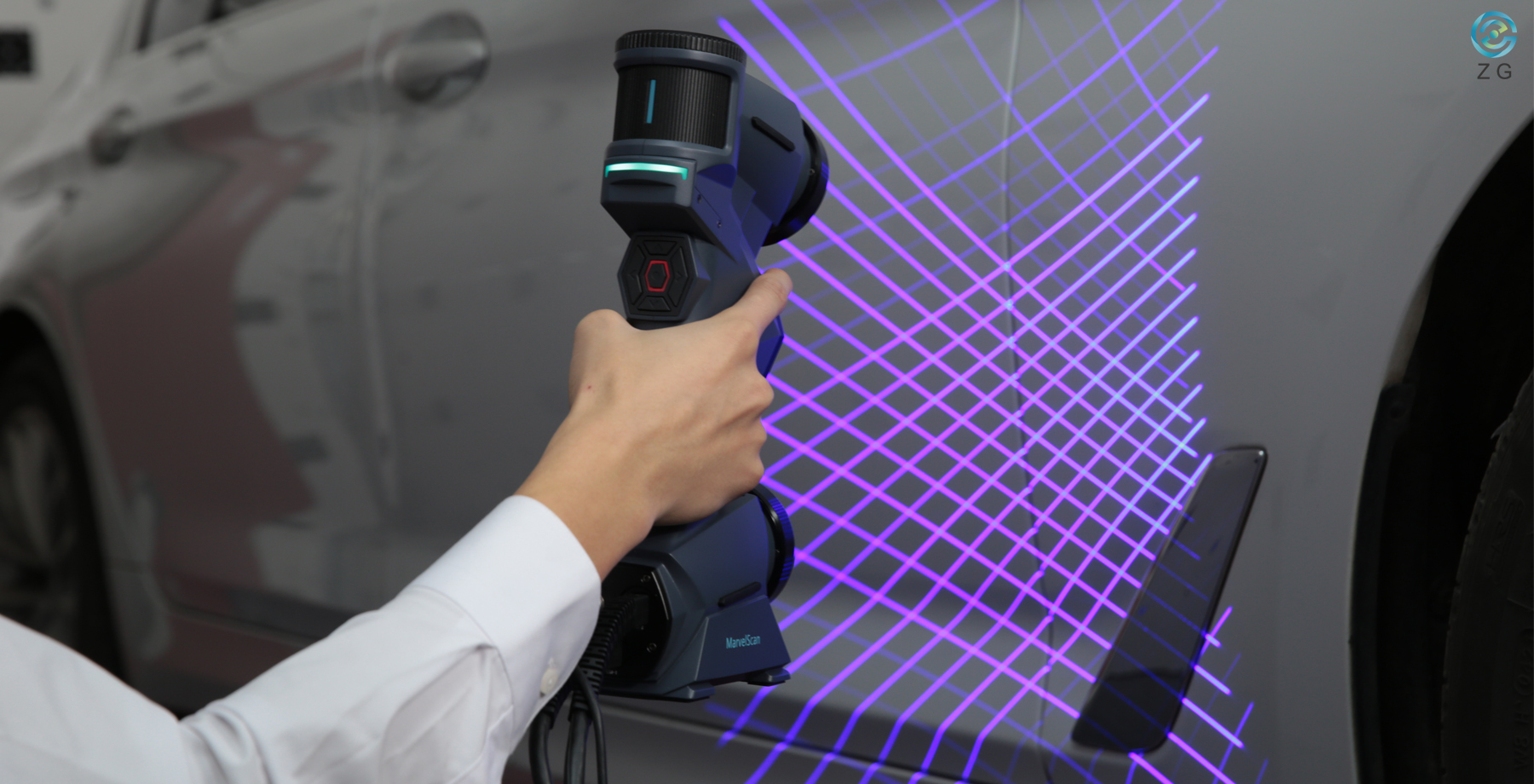

Most of the 3D scanners are designed to scan the object of a certain size. Typically, manufacturers offer different models of scanners to scan small objects (like ancient coins) or large objects (like cars). Some scanners are also able to scan the objects from a few centimeters to several meters like ZG’s revolutionary product—AtlaScan. Most of the 3D scanners require placing reflective markers on the surface of the object before scanning, if the object is extremely large, it will take a lot of time to just place the markers, in this case, you might be interested in ZG’s Marker-free 3D Laser Scanner—MarvelScan. So, knowing the size of what will be scanned can help you to choose a 3D scanner better.

MarvelScan---Tracker-Free & Marker-Free 3D Laser Scanner

3. What are your requirements for the 3D scanner?

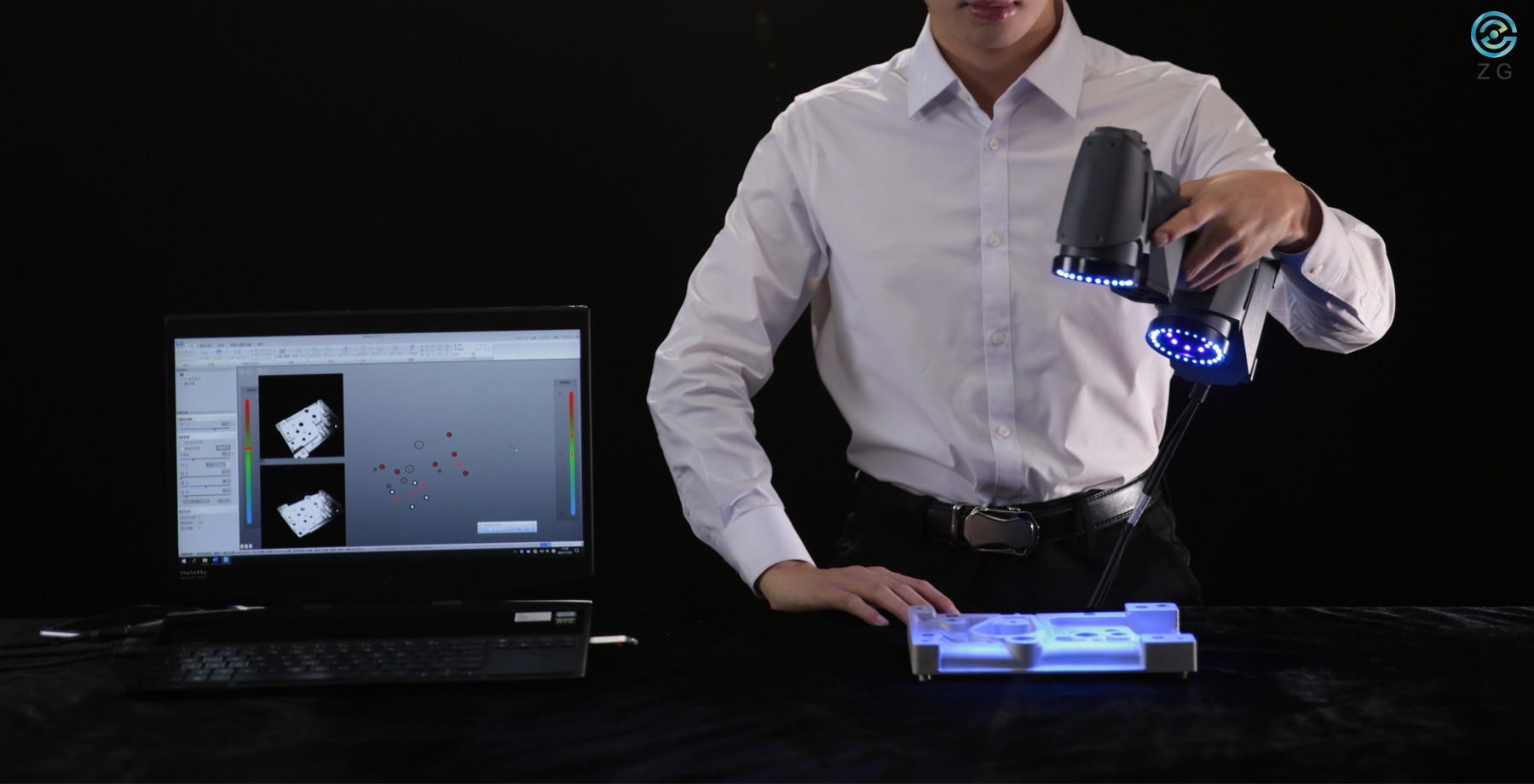

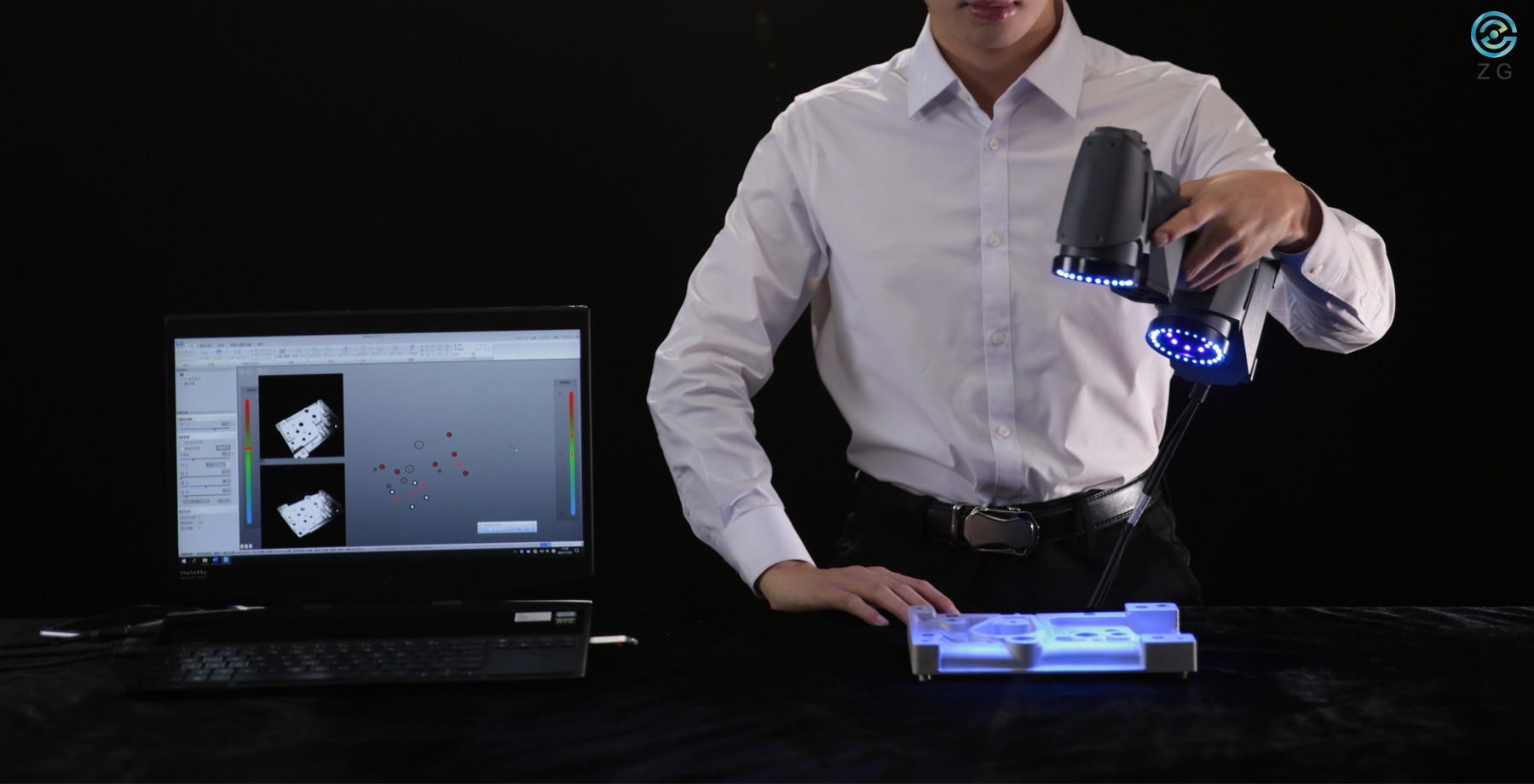

Your requirements for the 3D scanner normally depend on the accuracy and efficiency you want. For example, some objects, like large casting parts, require relatively low accuracy but high efficiency, so it needs a 3D scanner with Wide-range Mode, which can save a lot of time than regular 3D scanners. And if you need to scan a sheet metal to get the data of the holes, you should choose a 3D scanner with Hole Flash Capture Function, which can capture the data of holes accurately in seconds.

AtlaScan Ultra---Hole Flash Capture

AtlaScan Ultra---Wide-range Mode

4. What’s your budget?

Price is an important factor to take into consideration when making the decision. The features provided by the 3D scanner, as well as the accuracy and speed of data capture, will correspond to its cost.

Normally a 3D scanner costs from several thousands to over few hundred thousand USD. Less expensive 3D scanners might seem more appealing in the short term, but please look at the bigger picture because it’s a big investment. High quality devices are can definitely last longer and less likely to malfunction and will deliver better results for years to come.

Scanner Main Features

1. Accuracy

The accuracy is one of the most important features of a 3D scanner. It is measured in millimeters and normally from 0.01-0.1mm.

The accuracy of high-precision 3D scanners is from 0.01-0.03mm, they can provide the maximum quality of the scan data. Usually, they are used in the field that requires high accuracy, for example, the aerospace or automotive industry.

3D scanners with an accuracy of 0.03-0.1mm can be used in a wide range of applications. They are suitable for most basic tasks. But with the development of the times, the quality requirements are getting much higher, so the 3D scanners of this accuracy are gradually being eliminated.

The 3D scanner needs to be calibrated to get the best accuracy. To ensures the best possible accuracy of the device, all 3D scanners are initially factory calibrated. Onsite calibration is also possible for some 3D scanners. The configuration settings of the 3D scanner can be manually adjusted by the customer to meet the manufacturers’ optimal standards any time after the purchase.

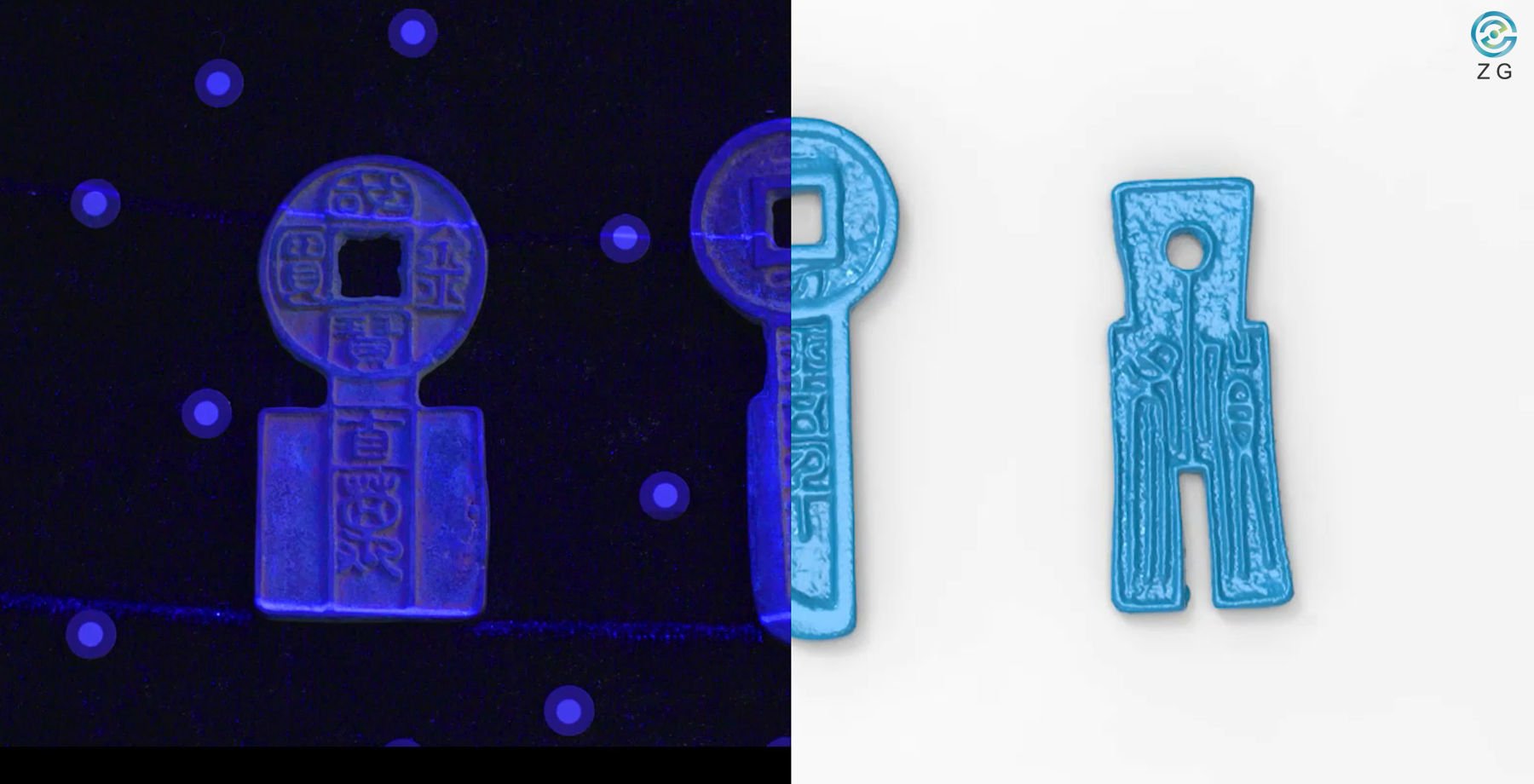

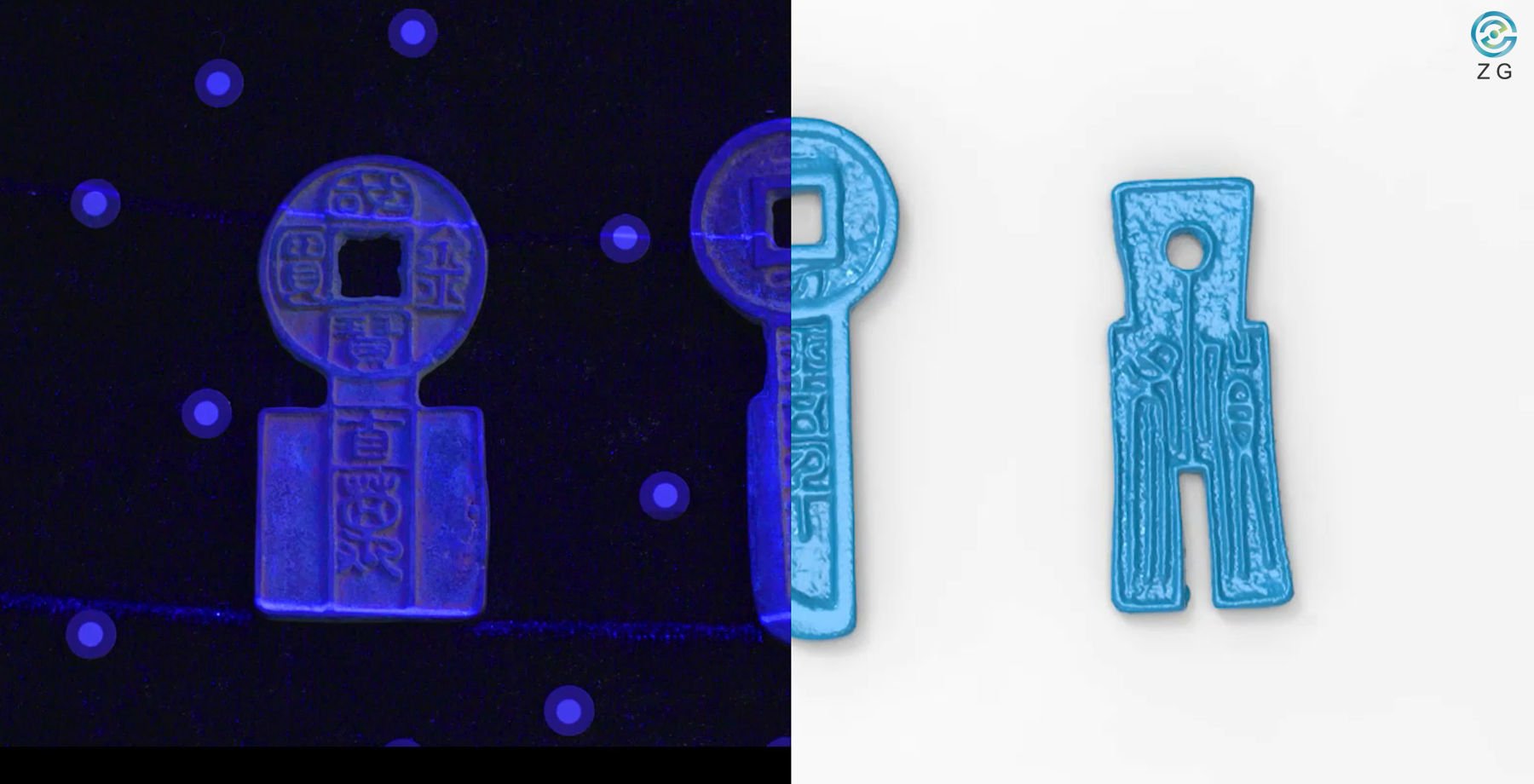

2. Resolution

The resolution of a 3D scanner is the least possible distance between two neighboring points on the 3D model. It is usually expressed by millimeters. The resolution affects the detail and the file size of the model. The higher the resolution, the denser the points cloud, the better the details. If you are looking to have an extremely detailed 3D model, you would use a high-resolution 3D scanner to do the job. This is especially important for applications in reverse-engineering, quality control, cultural preservation, animation, and VR, etc.

Detailed 3D Model of Ancient Coins

3. Measuring Rate

As the old saying goes, “Time is money”, that’s why the measuring rate of a 3D scanner is so important.

The measuring rate of a 3D scanner refers to how fast it can capture the surface data of the given object.

The measuring rate of a high efficiency handheld blue laser 3D scanner can be up to 2,100,000 measurements/s, which makes it possible to finish the scanning within minutes. Users can capture any object quickly with a faster 3D scanner to save unnecessary costs and boost productivity. This is especially important for large and costly projects on a tight schedule.

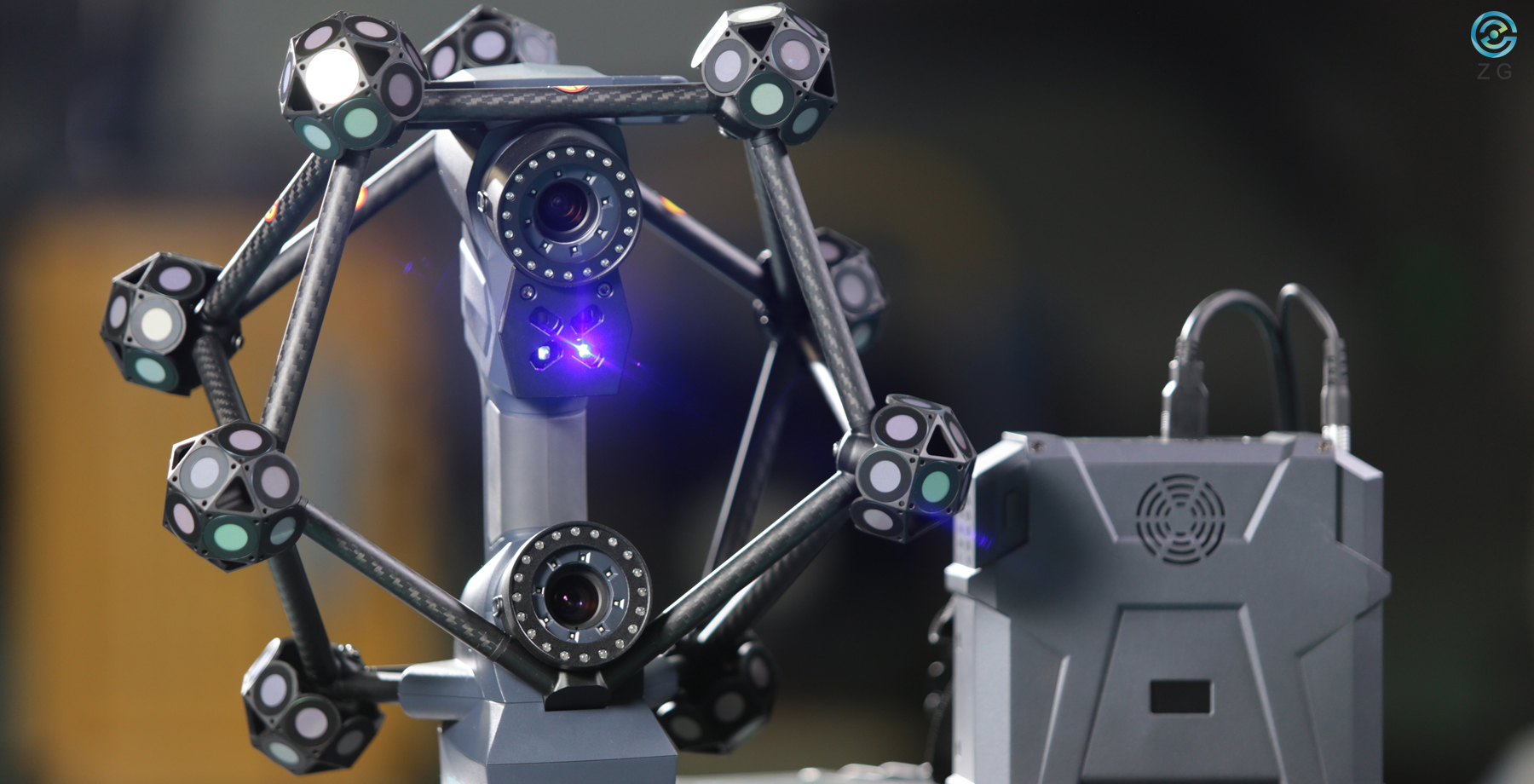

4. Portability

Portability means more possibilities to scan the object, which is one of the most important features of handheld 3D scanners. A handheld 3D scanner gives a much higher degree of control to the operate, making it a more flexible solution. The tricky angles and hard-to-reach places are now not a problem anymore.

It’s also a better choice for you to choose a 3D scanner that is able to work with a wireless module, so a nearby power source will not be required.

HyperScan Ultra with Wireless Module

Manufacturer

1. Manufacturer background

Before making the decision, it’s better for you to know who you are buying from. Basic research of the manufacturer’s background is recommended, like how big the company is, how’s the R&D team, how’s the comments from customers, etc. ZG Technology is a professional metrology-grade 3D scanner solution provider in China. Founded in 2014, relying on the background and technical advantages of Wuhan University's Photogrammetry and Remote Sensing disciplines, ZG Technology has always been at the forefront of 3D measuring technology.

2. Manufacturer service

Besides knowing who you are buying from, you also need to know what kinds of services the manufacturer can provide. For example, the warranty, training, repair, replacement, payment method, software updates, etc. You need to figure all of these things out before making the decision.

How can ZG Technology Help?

After knowing the main criteria for choosing the most suitable 3D scanner for your application, you can move to the demo stage now. It’s the best way to test the scanners and the software beforehand so that many unpleasant surprises can be avoided. ZG Technology is willing to offer 3D scanning solutions and also a one-on-one online demonstration. Talk to our experts today to find out more about 3D scanning technologies and how they can have a long-lasting impact on your business.