In the modern manufacturing world, ensuring the highest quality while maintaining production speed is vital for staying competitive. As industries across the globe continue to prioritize efficiency and precision, automated 3D scanning systems have emerged as an essential tool for achieving 100% inspection throughout the production process. These systems are designed to improve the overall quality control process, allowing manufacturers to detect defects at an early stage and prevent costly rework. ZG Technology provides cutting-edge automated 3D scanning solutions that help manufacturers reduce waste, enhance product quality, and boost productivity, which is a major step toward smart manufacturing.

What Is an Automated 3D Scanning System?

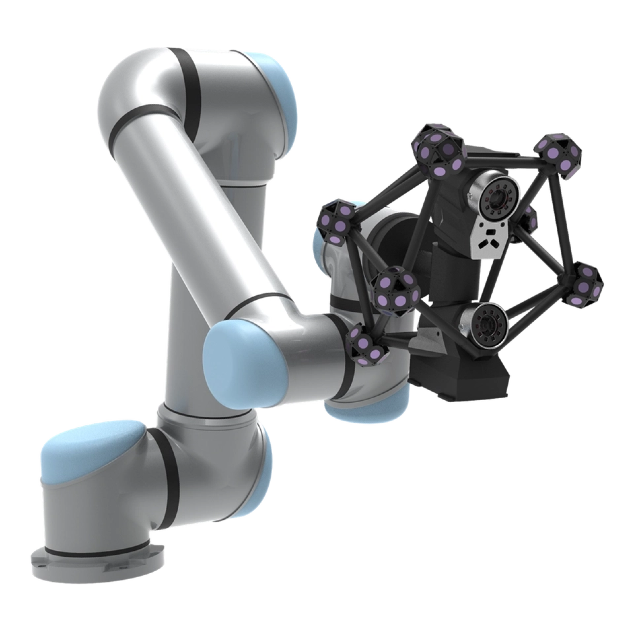

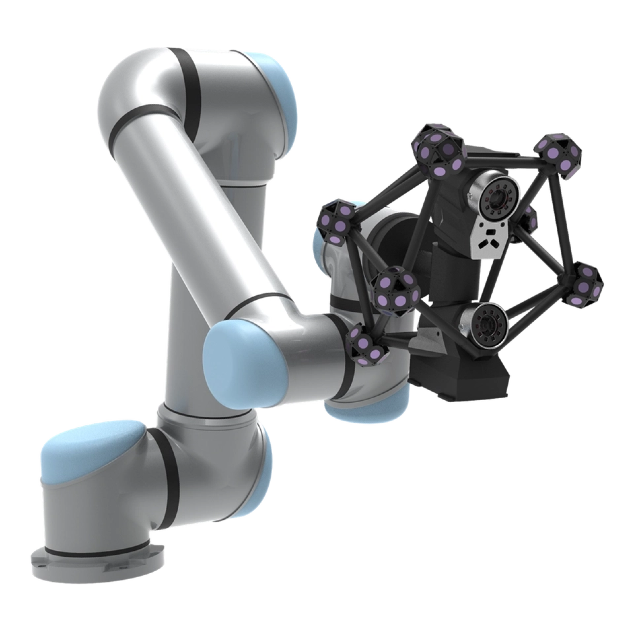

An automated 3D scanning system is an advanced technology that captures detailed, three-dimensional information about an object’s surface. This process is done through high-precision sensors, which measure the physical features of an object to create an accurate digital model. The system uses laser or structured light sensors to gather vast amounts of data from a product’s surface, which is then processed into a point cloud—a digital model consisting of millions of data points.

One of the key advantages of automated 3D scanning over traditional manual inspection is its ability to gather highly accurate and repeatable measurements in a fraction of the time. This makes it ideal for high-volume production environments where speed and precision are critical.

Key components of an automated 3D scanning system include:

3D Scanners: The devices that capture the geometric data from the object.

Sensors: Specialized tools like laser sensors or structured light cameras that ensure precision in measurement.

Software: Programs that process the collected data and compare it to pre-defined models to detect any discrepancies or defects.

Compared to manual inspection, which can be slow and prone to human error, automated 3D scanning systems offer faster, more accurate, and more consistent results, making them invaluable for industries that demand high precision.

How Automated 3D Scanning Systems Work in Smart Manufacturing

Automated 3D scanning systems integrate seamlessly into smart manufacturing environments, where precision, speed, and flexibility are necessary to meet production demands. These systems use high-speed data acquisition to capture real-time measurements as a product moves through the manufacturing line. The system creates a point cloud, a digital representation of the product’s surface, which is then compared against the digital CAD (Computer-Aided Design) model. This allows manufacturers to identify deviations or defects early in the process, minimizing the chances of defective products reaching the market.

Here’s how the system works:

High-Speed Data Acquisition: The scanner rapidly captures data points, creating an accurate digital model of the object’s surface. This process can occur as quickly as the object passes through the scanner.

Point Cloud Creation: The system processes the data into a point cloud, a dense collection of data points that represent the shape and surface features of the object.

Real-Time Digital Comparison: The point cloud is then compared to the original CAD model in real-time to detect any deviations or defects. The system can automatically flag parts that fall outside of acceptable tolerances, alerting the operator to potential issues before they become larger problems.

In addition, automated reporting and defect classification help manufacturers by categorizing defects and providing detailed information on the type and location of issues. This enables manufacturers to act quickly, reducing the risk of faulty parts moving further down the production line and preventing them from affecting the final product.

Subsection: Role in Digital Twin and Industry 4.0

Automated 3D scanning systems play a crucial role in the concept of Digital Twins—virtual representations of physical assets that help manufacturers simulate and optimize their processes. The data collected by 3D scanners can be used to create a digital twin of the product being manufactured, which can then be used for further analysis, testing, and optimization.

These systems also integrate with other elements of Industry 4.0, such as MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning), enabling manufacturers to make real-time adjustments based on the data collected from the scanning systems. By linking automated 3D scanning to predictive maintenance and adaptive processes, manufacturers can optimize their production schedules and maintain high operational efficiency.

Advantages of 100% Automated Scanning for Manufacturers

Accuracy & Consistency

The most significant advantage of automated 3D scanning systems is their ability to deliver exceptional accuracy and consistency. Unlike manual inspections, which can vary depending on the operator, automated 3D scanning systems provide consistent, repeatable results. This accuracy is essential in industries where even minor deviations can lead to serious consequences, such as aerospace or automotive manufacturing.

Faster Throughput & Reduced Inspection Cycle Times

In high-speed production environments, time is of the essence. Automated 3D scanning systems enable manufacturers to reduce inspection times significantly. Since the system can scan and analyze multiple parts simultaneously, manufacturers can maintain high throughput without sacrificing quality.

Furthermore, automated 3D scanning systems can work continuously without taking breaks or requiring rest, unlike human operators. This leads to increased productivity and ensures that production schedules are adhered to without delays caused by slow or inconsistent inspections.

Reduction in Scrap, Rework, and Returns

The ability to detect defects at an early stage in the production process means that defective parts can be identified and removed before they move further down the line. This reduces scrap and rework, which can be expensive and time-consuming. Additionally, the systems can prevent defective products from reaching customers, reducing the likelihood of returns and damage to a company’s reputation.

Subsection: Cost and Efficiency Benefits

While the initial investment in an automated 3D scanning system may be significant, the long-term benefits far outweigh the costs. By reducing the need for manual labor, manufacturers can save on labor costs. Additionally, by improving the overall efficiency of the production process and reducing defects, manufacturers can achieve a better return on investment (ROI).

Typical Use Cases Across Industries

Automated 3D scanning systems are used across various industries, each benefiting from the precision and speed these systems offer. Below are some of the most common use cases:

Automotive Inline Inspection

In the automotive industry, automated 3D scanning systems are used for inline inspection of critical components such as body panels, engine parts, and structural components. These systems ensure that each part meets strict quality standards before it is used in the assembly process.

Aerospace Component Validation

Aerospace manufacturing requires the highest level of precision, and automated 3D scanning is used to validate the measurements of complex aerospace components. Whether it’s turbine blades or fuselage components, these systems ensure every part meets the required specifications.

Heavy Equipment and Molds

Heavy machinery and large molds require high-precision measurements to ensure functionality and durability. Automated 3D scanning systems are used to inspect and measure these components, ensuring that they meet exact tolerances.

Consumer Electronics Quality Control

In the consumer electronics industry, automated 3D scanning systems are used to inspect delicate parts such as circuit boards, casings, and internal components. This ensures that products meet both aesthetic and functional requirements.

Challenges and Technical Considerations

Despite the many advantages of automated 3D scanning systems, there are some challenges to consider:

Initial Implementation Complexity

Implementing a new 3D scanning system can be complex, particularly for manufacturers unfamiliar with the technology. It may require system calibration, staff training, and software integration with existing systems. However, with proper planning and expert assistance, the implementation process can be streamlined.

Integration with Legacy Systems

For many manufacturers, integrating automated 3D scanning systems with legacy equipment can be a challenge. However, many modern 3D scanning systems are designed to be compatible with older systems, allowing for a smooth transition and enhanced functionality.

Training & Calibration Needs

Operators need to be properly trained to use the system effectively, and regular calibration is required to maintain accuracy. Manufacturers must ensure that their staff is adequately trained to operate and maintain the system, which can require ongoing investment in training.

Conclusion

To summarize, automated 3D scanning systems represent a revolutionary advancement in quality assurance for manufacturing. They allow manufacturers to conduct 100% inspection of products in real-time, improving the overall efficiency, accuracy, and consistency of the production process. By adopting this technology, manufacturers can significantly reduce defects, lower costs, and increase throughput. ZG Technology provides state-of-the-art automated 3D scanning systems that enable manufacturers to meet the demands of smart manufacturing and maintain the highest standards of quality.

For more information or to discuss how our automated 3D scanning systems can benefit your business, please contact us today!

FAQ

Q1: How can automated 3D scanning systems improve manufacturing quality?

A: Automated 3D scanning systems provide precise, real-time inspection of products, ensuring that defects are detected early and reducing scrap, rework, and returns.

Q2: Are automated 3D scanning systems difficult to implement in existing production lines?

A: While initial implementation may require training and calibration, modern systems are designed to integrate seamlessly with existing manufacturing setups.

Q3: What industries can benefit from automated 3D scanning systems?

A: Industries such as automotive, aerospace, heavy equipment, and consumer electronics benefit from the accuracy and efficiency of automated 3D scanning systems.

Q4: How do automated 3D scanning systems support Industry 4.0?

A: These systems enable real-time data collection and integration with factory systems like MES and ERP, supporting smart manufacturing processes and predictive maintenance.